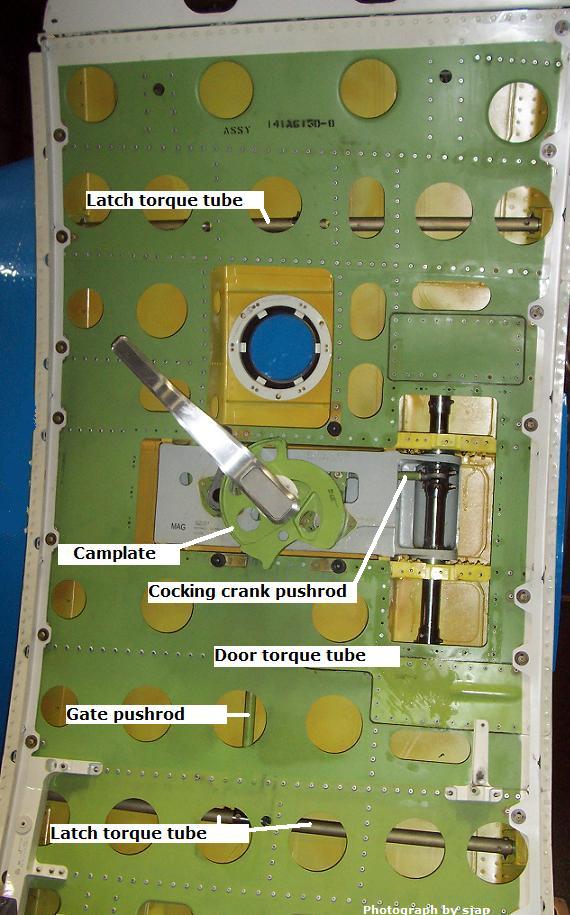

Sequence of adjustments:

1 – Gate pushrod.

2 – Latch-torque tube.

3 – Guidearm.

4 – Cockingcrank-pushrod.

5 – Door stops.

6 – Latchtracks.

7 – General.

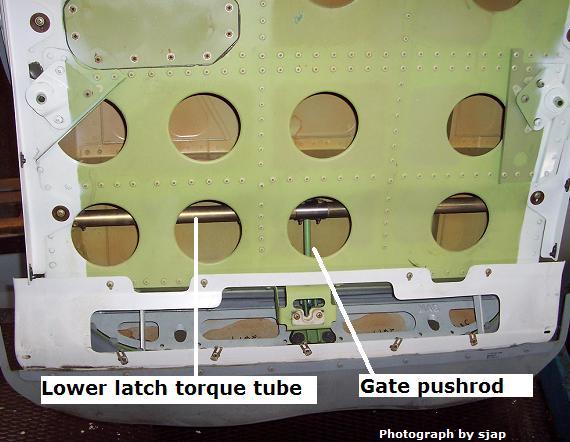

1) Gate pushrod.

The gate pushrod is properly adjusted, when the gates follow the door-profile. This is best checked with the door in open position. Disconnect the latching-pushrods from the latch torque tubes. Operate the gate manually full out. Some gates have stoprods. These do not belong to the adjustment mechanism, but they have to have the same adjustment.

2) Latch torque tube.

The latch torque tube is properly adjusted, when the gate-pushrod is just in the cocking position at the end of the travel of the door handle.

This is best checked with the door open position and cockingcrank-pushrod disconnected from the cockingcrankshaft. In this condition, the latching and gate-control mechanism can be operated without operating the door.

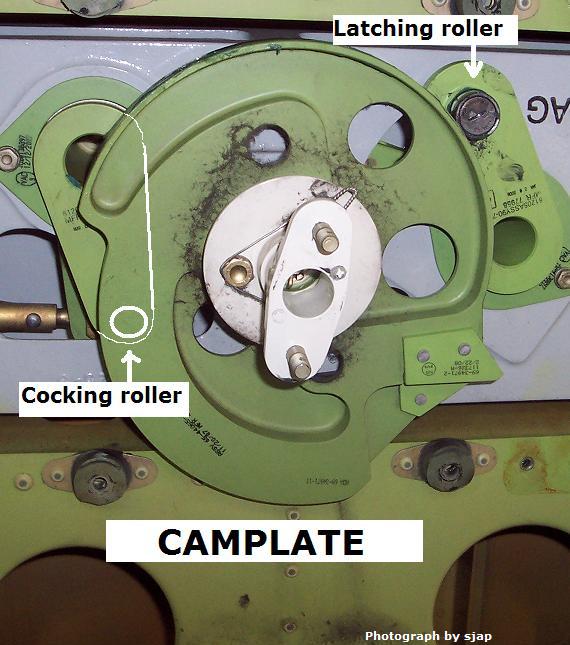

3) Guidearm.

The guidearm is properly adjusted if the door, just before the camplate operates the latchingcrank, is parallel to the fuselage.

In a normal condition, the door is about one to two cm inside the fuselage when the latchingcrank is operated by the camplate. If this is not the case, adjust first the cockingcrank-pushrod.

4) Cockingcrank-pushrod.

The cockingcrank-pushrod is adjusted properly, if the cockingcrankpushrod is tensionfree installed with the door in the closed position. The bolt must be possible to rotate by hand. Also the exterior controlhandle must be operated without friction in the stowed position.

5) The doorstops.

The stops are properly adjusted, if the distance between the doorskin and the doorstop is equal to the distance of the fuselageskin and the stopfitting.

Because the fuselage skin panels overlap and are bended, and the door is not always equally curved, it will be difficult to apply this rule for all the doorstops. Its best to adjust the stops near the latchtracks according to this rule. Thereafter, the other stops can be set if a cabin diffpressure of 1 psi is present or through a clay test. (~ 1 mm depressurized clay-over). When the controlhandle moves during this test, the latchtracks are not adjusted correctly.

6) Latchtracks.

The latchtracks are properly adjusted, if they are free from the latchtrack with a cabin diffpress of one to one and half psid. The door is then at the end stops, and there are no more forces present on the mechanism and the handle can easily moved a little bit. The latchtrack is about two millimeters larger

than the roller. The clay test should show more clay leftover on the outboard side than the clay leftover on the doorstops. (Pressureless ~ two mm clay-leftover).

7) General:

When the torque tubes (or bearings) are worn or the tubes are not properly mounted, it is possible that the door is too low in the door-opening. The hingearm plating and the snubber are then scraping in the recess. If this is not the case and the door is still too low, the door can be adjusted upwards relative to

the torque tube.

With the door closed, and at the top and bottom its not closing evenly (parralell) inside, the hingearms themselves ar not fastened enough anymore. This may be caused by loose or worn bolts, loose guide plates or loose bearing supports. If this causes excessive force to close the door, damage may occur at the mechanism. Often fastening of the door-torquetube bolts will help a lot.

Note that all adjustments are related to each other. This makes the adjustment of a 737 door a very difficult job, requiring experience over time. All adjustments have tolerances and it is sometimes possible to rectify a defect through the right mix of adjustments within the permitted values.

This text was written by R.Meijer in Dutch and translated in English using Google translate.

For the Dutch version click here.

See the pictures below for more clarification: